Do you really know how to maintain truck engines?

2021-03-04

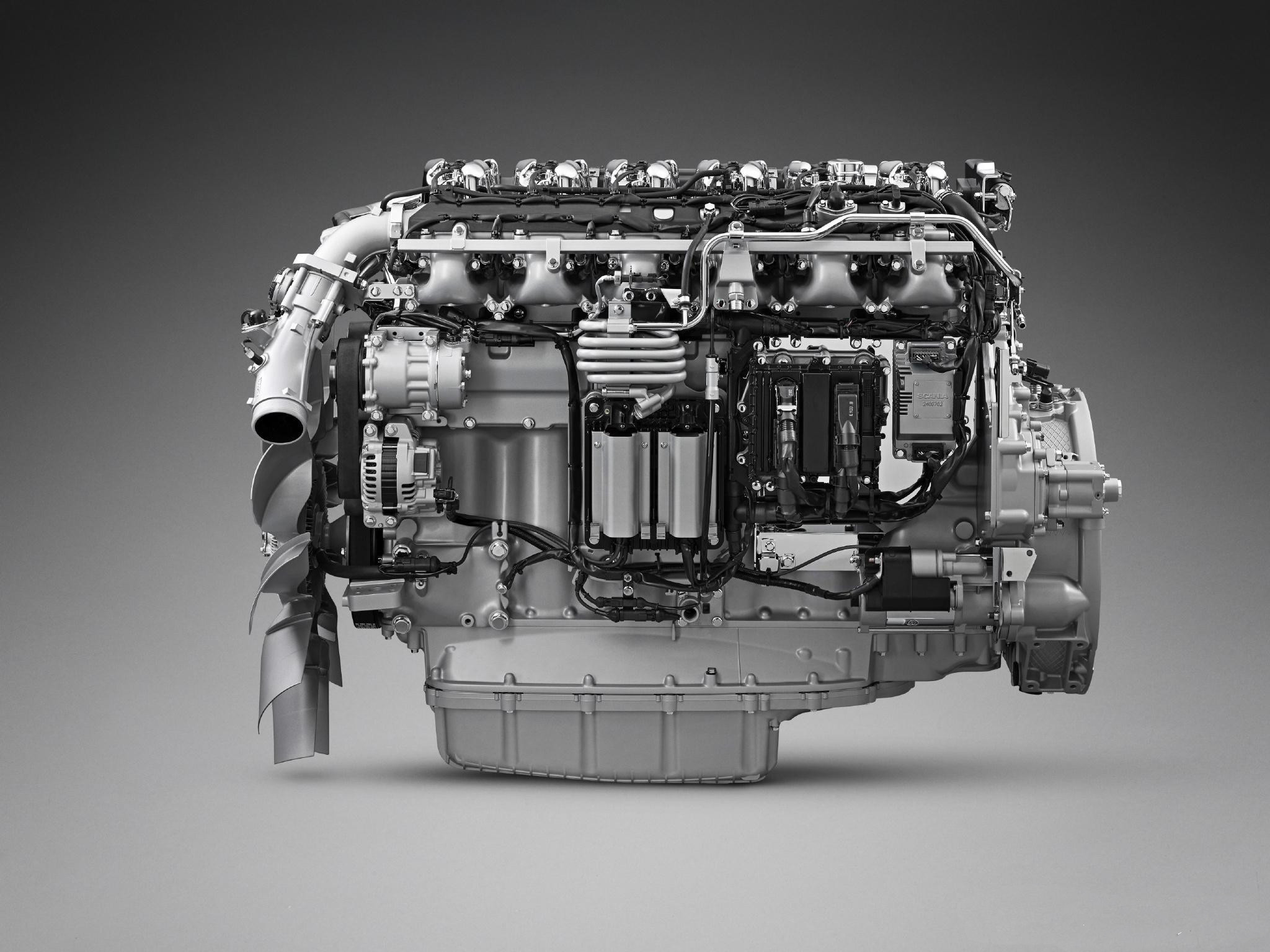

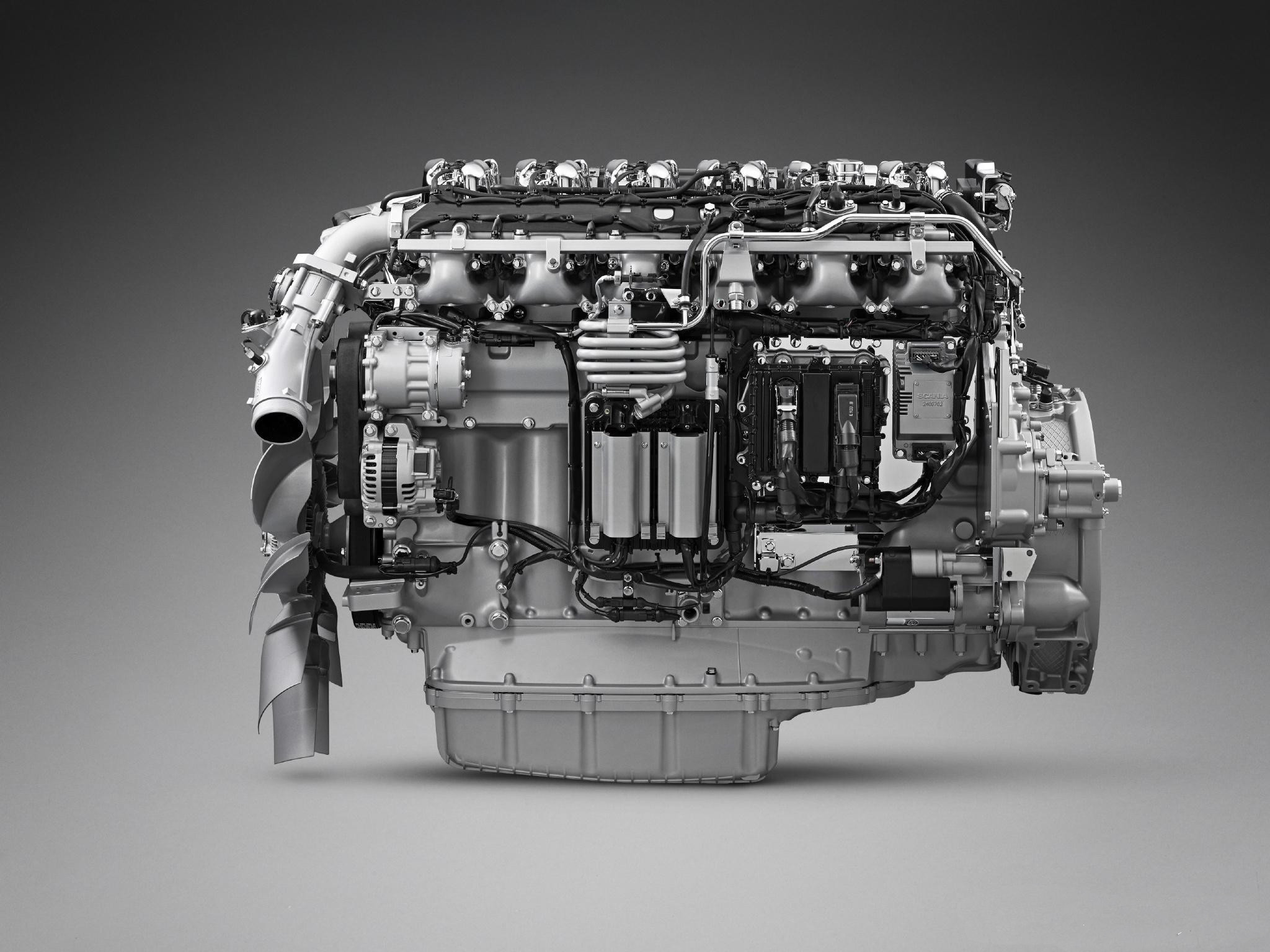

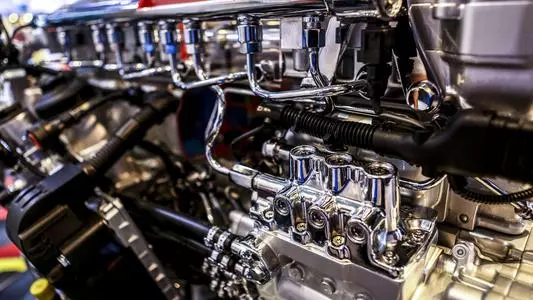

We have been driving for many years, and we have traveled thousands of miles. We have traveled in countless places. Count the stars and the moon on the winding mountain roads, and watch the waves of water on the long bridge. Trucks are our work, our lives, and our most trusted brother. But, have you ever thought that after such a long journey, the "heart" can bear the mountains and the seas? Here, let’s share some tips about the heart of the truck-the engine.

Trucks have to do too much work in a year, and they have to run too far. It can be said that the burden of a family is carried on this car. If there is a problem with the engine, like a heart attack, it will be a huge loss of energy and financial resources. In order to make our journey smooth, and to realize our "little dream" on the transportation road as soon as possible, let's learn from Fage how to avoid misunderstandings and carry out engine maintenance reasonably!

One of the misunderstandings of maintenance: Irregular maintenance has been mentioned before, and irregular maintenance is a mistake that many card friends will make. Regular maintenance of the engine is very important. Many professional repairers say that in the trucks they handle, failures caused by poor engine maintenance account for 50% of the total failures. It can be seen that engine maintenance can play a great role in prolonging the service life of the vehicle. Important role. It is not only the maintenance of the engine during the regular maintenance period, but also the inspection and maintenance of the relevant parts of the engine after driving through some particularly humid or dusty areas.

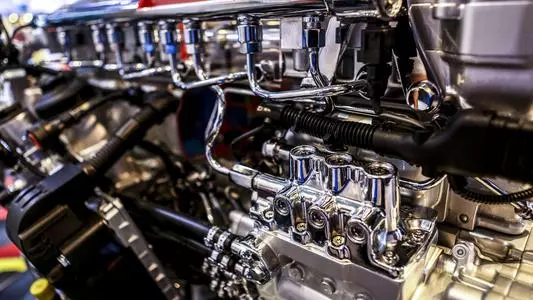

Maintenance misunderstanding two: engine oil deterioration and oil filter element is not smooth The oil quality of different grades of lubricating oil will change during the use process. After a certain mileage, the performance of the vehicle will deteriorate, which may cause various problems to the engine. In order to avoid the occurrence of these failures, the car should be changed regularly according to the conditions of use, and the amount of oil should be moderate, generally between the upper and lower limits of the oil scale. Regular replacement of the oil filter is equally important.

Maintenance misunderstanding No. 3: Air filter plugging the air intake system of the engine is mainly composed of two parts: air filter and intake duct. According to different usage conditions, the air filter element should be cleaned regularly. The available method is to blow high-pressure air from the inside out to blow out the dust in the filter element. Since the air filter element is made of paper, pay attention to the air pressure not to be too high when blowing, so as not to damage the filter element. The air filter element should generally be replaced after 3 times of cleaning. The cleaning cycle can be determined by the air quality in the daily driving area.

Maintenance misunderstanding 4: The intake duct is too dirty. If the vehicle often drives in dusty and poor air quality road conditions, you should pay attention to cleaning the intake duct to ensure that the air intake is unblocked. The intake duct is very important for the normal operation of the engine. If the intake duct is too dirty, it will cause a decrease in efficiency, which will make the engine unable to operate within the normal output power range, and aggravate the wear and aging of the engine.

Maintenance misunderstanding No. 5: Too much sludge in the crankcase During the operation of the engine, the high-pressure unburned gas, acid, moisture, sulfur and nitrogen oxides in the combustion chamber enter the crankcase through the gap between the piston ring and the cylinder wall. It is mixed with the metal powder produced by the wear of the parts to form sludge. A small amount of sludge can be suspended in the oil, and when the amount is large, it will separate out from the oil, blocking the filter and oil holes, causing difficulty in lubrication of the engine, and aggravating the wear of the engine. Choosing high-quality fuel and synthetic diesel engine lubricants is particularly important for reducing the production of sludge. Therefore, it is recommended that car owners purchase synthetic diesel engine lubricants and fuels suitable for your car through formal channels as much as possible.

Maintenance misunderstanding No. 7: Rust and scaling of the water tank are the most common problems. To avoid the generation of scale, attention should be paid to the selection of coolant in the water tank. Many car owners do not pay attention to the use and quality of the coolant, and usually only ordinary water is added to the water tank. The most common problems in cooling systems are rust, scaling, and corrosion. The main reason for this is that no good antifreeze is used. A good antifreeze not only has a low freezing point, but also has various other functional additives, which can inhibit foam, rust, electrolysis, and scale, etc. Therefore, we should remind the majority of cars to choose the coolant that is beneficial to the water tank carefully.

Maintenance Misunderstanding No. 8: The cooling system is in poor condition. The most common failures of truck engines, such as piston pulling, knocking, internal leakage of cylinder punch, severe noise, and drop in acceleration power, are all due to the abnormal working temperature of the truck engine. Excessive pressure caused by poor cooling system condition. Poor cooling system conditions will directly cause the engine to fail to work at normal temperatures, and the above-mentioned serious failures will follow. The traditional maintenance method of the cooling system is to drain the water in the water tank and add antifreeze and water, but in this case, there will be a large amount of scale in the cooling system that is not clean, and the residual scale in the pump, water jacket, and pipeline will be even greater. Can not be discharged. Therefore, it is necessary to regularly clean the rust and corrosion in the water tank and the cooling system with a powerful and efficient cleaning agent for the water tank, and then add appropriate antifreeze and purified water. In this way, the normal operation of the engine can be ensured, and the overall life of the water tank and the engine can be prolonged.

In other words,maintenance is the key. Only regular maintenance of various parts of the truck, the use of original genuine parts and qualified oil, etc., can extend the service life of the truck engine.Tarzan wish you all have a strong "big heart"!

Trucks have to do too much work in a year, and they have to run too far. It can be said that the burden of a family is carried on this car. If there is a problem with the engine, like a heart attack, it will be a huge loss of energy and financial resources. In order to make our journey smooth, and to realize our "little dream" on the transportation road as soon as possible, let's learn from Fage how to avoid misunderstandings and carry out engine maintenance reasonably!

One of the misunderstandings of maintenance: Irregular maintenance has been mentioned before, and irregular maintenance is a mistake that many card friends will make. Regular maintenance of the engine is very important. Many professional repairers say that in the trucks they handle, failures caused by poor engine maintenance account for 50% of the total failures. It can be seen that engine maintenance can play a great role in prolonging the service life of the vehicle. Important role. It is not only the maintenance of the engine during the regular maintenance period, but also the inspection and maintenance of the relevant parts of the engine after driving through some particularly humid or dusty areas.

Maintenance misunderstanding two: engine oil deterioration and oil filter element is not smooth The oil quality of different grades of lubricating oil will change during the use process. After a certain mileage, the performance of the vehicle will deteriorate, which may cause various problems to the engine. In order to avoid the occurrence of these failures, the car should be changed regularly according to the conditions of use, and the amount of oil should be moderate, generally between the upper and lower limits of the oil scale. Regular replacement of the oil filter is equally important.

Maintenance misunderstanding No. 3: Air filter plugging the air intake system of the engine is mainly composed of two parts: air filter and intake duct. According to different usage conditions, the air filter element should be cleaned regularly. The available method is to blow high-pressure air from the inside out to blow out the dust in the filter element. Since the air filter element is made of paper, pay attention to the air pressure not to be too high when blowing, so as not to damage the filter element. The air filter element should generally be replaced after 3 times of cleaning. The cleaning cycle can be determined by the air quality in the daily driving area.

Maintenance misunderstanding 4: The intake duct is too dirty. If the vehicle often drives in dusty and poor air quality road conditions, you should pay attention to cleaning the intake duct to ensure that the air intake is unblocked. The intake duct is very important for the normal operation of the engine. If the intake duct is too dirty, it will cause a decrease in efficiency, which will make the engine unable to operate within the normal output power range, and aggravate the wear and aging of the engine.

Maintenance misunderstanding No. 5: Too much sludge in the crankcase During the operation of the engine, the high-pressure unburned gas, acid, moisture, sulfur and nitrogen oxides in the combustion chamber enter the crankcase through the gap between the piston ring and the cylinder wall. It is mixed with the metal powder produced by the wear of the parts to form sludge. A small amount of sludge can be suspended in the oil, and when the amount is large, it will separate out from the oil, blocking the filter and oil holes, causing difficulty in lubrication of the engine, and aggravating the wear of the engine. Choosing high-quality fuel and synthetic diesel engine lubricants is particularly important for reducing the production of sludge. Therefore, it is recommended that car owners purchase synthetic diesel engine lubricants and fuels suitable for your car through formal channels as much as possible.

Maintenance misunderstanding No. 7: Rust and scaling of the water tank are the most common problems. To avoid the generation of scale, attention should be paid to the selection of coolant in the water tank. Many car owners do not pay attention to the use and quality of the coolant, and usually only ordinary water is added to the water tank. The most common problems in cooling systems are rust, scaling, and corrosion. The main reason for this is that no good antifreeze is used. A good antifreeze not only has a low freezing point, but also has various other functional additives, which can inhibit foam, rust, electrolysis, and scale, etc. Therefore, we should remind the majority of cars to choose the coolant that is beneficial to the water tank carefully.

Maintenance Misunderstanding No. 8: The cooling system is in poor condition. The most common failures of truck engines, such as piston pulling, knocking, internal leakage of cylinder punch, severe noise, and drop in acceleration power, are all due to the abnormal working temperature of the truck engine. Excessive pressure caused by poor cooling system condition. Poor cooling system conditions will directly cause the engine to fail to work at normal temperatures, and the above-mentioned serious failures will follow. The traditional maintenance method of the cooling system is to drain the water in the water tank and add antifreeze and water, but in this case, there will be a large amount of scale in the cooling system that is not clean, and the residual scale in the pump, water jacket, and pipeline will be even greater. Can not be discharged. Therefore, it is necessary to regularly clean the rust and corrosion in the water tank and the cooling system with a powerful and efficient cleaning agent for the water tank, and then add appropriate antifreeze and purified water. In this way, the normal operation of the engine can be ensured, and the overall life of the water tank and the engine can be prolonged.

In other words,maintenance is the key. Only regular maintenance of various parts of the truck, the use of original genuine parts and qualified oil, etc., can extend the service life of the truck engine.Tarzan wish you all have a strong "big heart"!

Share: